Archive for January 16, 2009

Villu Movie Review

Villu – Loose strings

The hype and hoopla surrounding Villu, prior to its release was huge. Director Prabhudeva and actor Vijay promised lots of entertainment. Unfortunately the end product is far from impressive as it is a ‘chaotic’ cocktail of comedy, action and needless stunt sequences far from any logic.

Prabhudeva is greatly impressed by Abbas – Mastan’s Bollywood hit Soldier. But in trying to remake the movie, he has far-stretched his imagination, which fails to find its way with audience’s favour.

It’s a wholesome Vijay show. The actor is at his best – be it the stunt sequence, comedy or romantic episodes. There is an aura of style in whatever he ventures to do on screen. He is as usual cool in his mannerisms. Prabhudeva portrays him an invincible one-man army who floats on water and fly on air with ease and élan. But his hard labour is foiled by wafer-thin storyline, which has no logic.

The story is as old as that of lithic age – an angry son who taking revenge on those responsible for the death of his father. Vijay enacts a dual role – that of a son and father. Prabhudeva has laced it with commercial elements including comedy and action.

The movie revolves around a macho-man Pughazh (Vijay). Thanks to the help of Joseph (Manoj K Jayan), a honest cop, Pughazh begins his search for a international gangster and arms supplier JD (Prakashraj). Meanwhile, Pughazh goes to a village to attend a wedding and comes across Jhanvi (Nayantara). After cat and mouse games, love blossoms between them. Pughazh comes to know that she is the daughter of JD. He sets to Munich in Germany to meet JD along with Jhanvi. He meets JD’s gang (Sriman, Anandhraj and Devaraj). After initial encounters, he evolves his own plans and starts eliminating them one after another.

A flashback reveals why Pughazh is behind their blood. His father ‘Major’ Saravanan (Vijay) gets killed by a gang, which is led by JD, when he prevents them from selling arms to ultras. JD and his team enact a drama and bumps off Saravanan before managing to create an impression that he was the one who had nexus with ultras and succeeds in branding him an anti-national. Eventually Pughazh manages to bring JD to India and avenge them for their wrong-deeds and establish his father’s innocence

Vijay walks away with all honours, while Nayanthara catches the imagination of the audience appearing in skimpy costumes appearing in peppy numbers with Vijay. Vadivelu tries his hand at evoking comedy and succeeds fairly especially the scenes involving Vijay, Nayantara and himself.

Prakashraj platys a clichéd don who controls international arms racket. His dialogues and acts are far too predictable. The rest of the cast including Geetha, Ranjitha, Devaraj, Anandhraj play their part on screen.

Devi Sri Prasad has come up with some peppy numbers while Raviverman’s cinematography is passable. Thanks to Fefsi Vijayan’s stunts Vijay has belied law of gravitation. The real scene-stealer is however the producers Ayangaran Internationals, who have come out with a grand venture. Almost every frame is rich and lavish.

On the whole, Vijay’s Villu is a action-packed mass masala film for his ardent fans but with loose ends

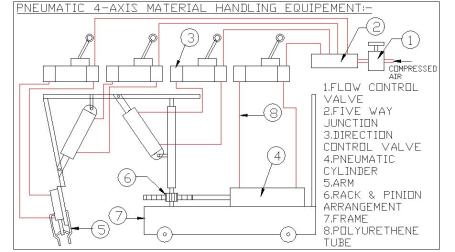

PNEUMATIC FOUR-AXIS MATERIAL HANDLING EQUIPMENT

SYNOPSIS

The technology of pneumatics has gained tremendous importance in the field of workplace rationalization and automation from old-fashioned timber works and coal mines to modern machine shops and space robots. Certain characteristics of compressed air have made this medium quite suitable for used in modern manufacturing and production industries. It is therefore important that technicians and engineers should have a good knowledge of pneumatic system, air operated valves and accessories.

A pneumatic system consists of a compressor plant, pipe lines, control valves, drive members and related auxiliary appliances. The air is compressed in an air compressor and from the compressor plant the flow medium is transmitted to the pneumatic cylinder through a well laid pipe line system. To maintain optimum efficiency of pneumatic system, it is of vital importance that pressure drop between generation and consumption of compressed air is kept very low. Pneumatic material handling system is used to move the components from one place to another with a maximum weight of 3.5 kg. It is used in the following places:

- Chemical laboratories

- Welding

- Foundry, etc.

INTRODUCTION

Material handling is a specialized activity for a modern manufacturing concern. It has been estimated that about 60-70% of the cost production is spent in material handling activities.

Need for material handling:

· Reduction of lab our and material cost

· Reduction of overall cost

· Increased production

· Increased storage capacity

· Increased safety

· Reduction in fatigue

· Improved personnel comfort

WORKING PRINCIPLE

The experimental setup consist of four cylinders, all are of double acting type. The cylinder1 is used to actuate rack and pinion assembly, piston rod of cylinder 1is connected to rack, which is meshed with the pinion. By operating the cylinder1, rack and pinion turns the whole assembly for 260°. By varying the length of the rack the turning angle can be altered. Vertical cylinder or cylinder2 is used to increase the height of the setup. The height is limited to piston rod length. Horizontal cylinder or cylinder3 is used to increase the arm length, the working area of the arm is limited to length of the piston rod length. Gripper cylinder or cylinder4 is used to actuate the gripper.

APPLICATIONS

- Discharge of work piece

The arm feed has a wide application in low cost automation industries. It can be used in automated assembly lines to pick up the finished product from workstation and place them in bins. it can also be used to pick raw material and place them on the conveyor belts.

- Work clamping

This unit can also be used in clamping. Operation in certain areas of mass production where clamping and an clamping have to be done at high speeds. The application of these units is limited to operations which involved moderate clamping forces.

§ Tool Changing Application

When the pneumatic arms are made smaller in size they can be used in automatic tool changes in CNC turning and drilling machines, by attaching tool holding device to the rotary cylinder

ADVANTAGES

The pneumatic arm is more efficient in the technical field

- Quick response is achieved

- Simple in construction

- Easy to maintain and repair

- Cost of the unit is less when compared to other robotics

- No fire hazard problem due to over loading

- Comparatively the operation cost is less

- The operation of arm is faster because the medium used to operate is air

- Continuous operation is possible without stopping

LIMITATIONS

- While working, the compressed air produces noise therefore a silencer may be used.

- High torque can not be obtained

- Load carrying capacity of this unit is not very high.(<50N)

Recent Comments